| Thermal Integration TI-A8641L

Heatsink From All Angles |

|

The Fan:

The 70mm fan is the standard

size for all mainstream PCs on the market. Larger 80mm and even 92mm fans

are starting to make headway

with some custom cooling solutions, but they can be difficult to fit into all case situations. The fan draws

0.4A and rotates at 3800 RPM to provide the necessary airflow to keep back pressure from becoming

an issue. The fan connects to a standard 3-pin motherboard fan header. |

|

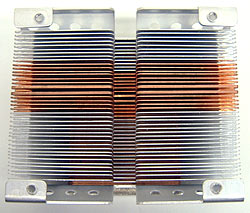

Heatsink Top:

After unscrewing the fan

from the aluminum fan shroud which supports it 4mm above the tips of

fins, we can get a better look at how things work. The

aluminum fins are positioned towards the outer edges of the heatsink where

there is no direct contact with the CPU core. Directly over the

center of the CPU core are two thick copper fins that support the

forces the retention clip applies to the heatsink. Surrounding them is 18mm worth of copper

fin. It is this area of the heatsink which comes in contact with the

processor core. |

|

Side A:

Each fin measures 0.3mm thick and is spaced 1.0mm

apart.

The two central

fins which support the clip, and indeed the entire

weight of the heatsink when it is installed are both 1mm thick. The Fins are

all 40mm tall, though their edges are slightly patterned. The base measures 10mm thick,

and the single spring clip uses all three catches to latch on to the processor

socket. |

|

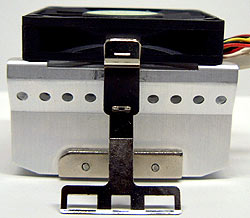

Side B:

Some vents

along the outer edges of the fan shroud

are for decorative purposes undoubtedly. Given the 470 gram weight of the

Thermal Integration TI-A8641L,

it is not surprising that the manufacturer opted to use a

three-prong clip mechanism which offers a little more lateral support. Also note the steel wedge the

bolts are screwed into - it is this which keeps the entire heatsink from falling into

pieces. |

|

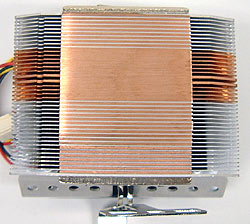

Heatsink Base:

With the heatsink assembled, a machining or sanding operation has been done to the

base to smooth out the individual copper and aluminum fins. The base finish is pretty flat

all things considered. The surface roughness is typical of such sanding

operations. |