|

|

0%

Abstract: Frostytech departs from the usual pixel fodder for a brief look at some cooling technologies you have never seen before. We touch on some fun tests from the unpublished Frostytech archives and collect all the thermodynamics research we've reported on into one location.

|

Home >

Reviews >

Page: Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

|

Chemical Vapor Deposition Diamond Heat

Spreaders :

Ever wonder what the next generation cooling

technologies are for cooling next generation processors? Chemical Vapor

Deposition Diamond surfaces is one. Diamond is applied to silicon

processors to improve surface thermal conductivity substantially according

to this report from the University of Maryland. Of course the high cost of

producing diamond heatspreaders means that more economical alternatives

like Electroless Nickel, with a thermal conductivity of 90.7 W/m/K, could

also work.

Other exotic cooling technologies mentioned in the

VITA report include;

- Heat Pipes

- Liquid Cooling

- Spray Evaporative Cooling

- Chip Refrigeration (Phase Change Cooling)

- Cryogenic Cooling

- Thermoelectric Cooling

- Non-Metallic Microchannels

- Meso / Micro Cold Plates

|

Fraunhofer Institute's 100 µm-density heat

exchanger:

The Fraunhofer Institute for

Manufacturing and Advanced Materials (IFAM) has

pioneered metal fiber structures, along with hollow spheres structures and

metal foams. In the case pictured below, Direct Typed structures are

printed with gas atomized 316L stainless steel. Given the right design,

you could be looking at some of the worlds best potential heat exchangers

here...

"A printable suspension of metal powder and a binder

is pressed in a screen printing process through a computer generated mask,

followed by a hardening step. In the next step a layer-on-layer printing

is repeated until a 3-dimensional part is manufactured. A first heat

treatment is applied to remove the organic binder; subsequently the

remaining metal powder is sintered to structures with high precision and

good mechanical stability. The residual minimal wall thickness and channel

width amounts about 100 µm. In contrast, the maximal structure height may

add up to a couple of centimeters. Hence, exceedingly high aspect ratios

are feasible.

The method enables the production of 3-dimensional

structures with horizontal apertures or closed channels."

|

|

Tamagawa Zigzag Heatsink Fin Concept:

Tamagawa, a Japanese metal products

company, has developed a very unique heatsink fin concept for what it

calls 'advanced cooling' situations. The heatsink fins are formed into a

zigzag pattern, composed of offset micro squares stacked on top of one

another to form fins about 10-30mm tall.

The surface area and complex flow patterns that would result from such

complex interlocking fins may possibly produce a very efficient thermal

shape for increasing heat dissipation in limited spaces. We would expect

that high-volume forced air cooling would be used to combat the pressure

drop.

Shown are two examples of Tamagawa's 'zigzag' cast

aluminum and cast copper heatsink concepts. The copper prototype measures

just 40x20x10mm in size, the aluminum model appears to be somewhat larger.

|

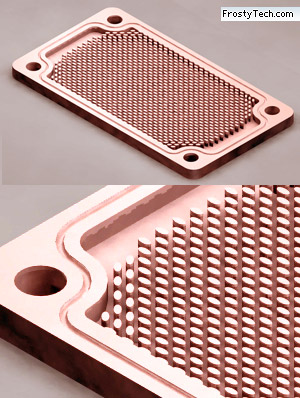

Injection Molded Copper from Amulaire:

Most aluminum heat sinks exist as extrusions

that allow intricate shapes in only two dimensions. "By injection molding

copper, though, engineers have more control over the intricate shapes on a

heat sink," said Ken Kaskoun, VP of Sales and Marketing at Amulaire

Thermal Technology. "Molded copper lets us increase the amount of metal

over the chip and then taper off the base thickness at the heat-sink edges

or we can create an airfoil to increase air flow across an area," said

Kaskoun. The molding process also lets customers include mounting features

without the need for machining. To create a molded-copper heat sink,

Amulaire simulates a design and then machines one or two

prototypes."

"Unlike plastic, you cannot inject

molten copper into an intricate mold. Instead, Amulaire Thermal

Technology combines fine copper with a polymer binder and injects the mix

into the mold. "The part comes out of the mold with the consistency of

chocolate," said Ken Kaskoun, VP of Sales and Marketing at Amulaire. It

then goes into a sintering oven that drives off the binder and leaves the

fused copper behind. The design shrinks uniformly by about 20 percent as

it goes from the molded to the sintered state, said Kaskoun. "After

sintering, we have a copper part that has 98 percent of the density of

solid copper." |

|

|

|

1:

Cryo Tech and New Cooling Technologies You Have Never Seen

2:

Thermoacoustic Cooling

3:

Phase Change Waterchilling

4:

Conduction PCB Cooling via Cold Plate Heat Exchangers

5:

The Stirling Cycle Cryo Cooler

6:

Annex. A) Graphite, Carbon Foam/Fiber, Polymer Heatsinks

7:

Annex A) Graphite, Carbon Foam/Fiber, Polymer Heatsinks

8:

Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

9: — Annex B) Diamond, Nano-structure and Metal Foam Heatsinks

10:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

11:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

12:

Annex C) Heat Exchangers, Microchannel, Capilliary, Spray Watercooling

13:

Annex D) Computational Fluid Dynamics and Innovative Heatsink Tech

List all FrostyTech heat sinks that Frostytech tested?

|

|

|

|

|

Websites you may also like:

PCSTATS

|

|

|